Choosing Aluminium Frame Doors for Your Home

Table of Contents

What Makes Aluminium Different?

Modern aluminium frame doors stand apart from other materials through their unique mix of physical properties. The metal’s molecular structure creates an exceptional strength-to-weight ratio, allowing for thinner frames that don’t compromise on stability. Unlike traditional materials, aluminium maintains its shape and won’t warp or twist over time.

The Science Behind the Strength

Raw aluminium undergoes extensive processing to become suitable for door frames. The metal’s atoms arrange themselves in a face-centred cubic crystal structure, creating natural resistance to various types of stress. This arrangement produces frames that withstand daily use without showing signs of wear.

Much of the durability of aluminium comes from its oxide layer, which forms instantly when exposed to air. This microscopic barrier acts like a shield, preventing corrosion from reaching deeper into the metal. When manufacturers apply surface treatments to aluminium framed doors, this protection grows even stronger.

Weather Performance

British weather puts door frames through constant cycles of rain, sun, and temperature changes. Aluminium glass doors excel in these conditions because of their thermal stability—they don’t expand or contract much with temperature swings. Salt spray from coastal areas won’t cause pitting or degradation, while urban pollution simply washes away during rainfall.

The material’s inherent energy efficiency stems from proper thermal break design. Modern aluminium frame doors use polyamide strips between their internal and external faces, blocking heat transfer effectively. This technology prevents the thermal bridging issues that plagued older aluminium systems.

Types of Aluminium Frame Doors

Well-designed aluminium frame doors come in several distinct styles, each with specific opening mechanisms and purposes. The material’s strength allows for larger glass panels and thinner frames compared to other materials, making it particularly popular for modern homes.

Sliding Patio Doors

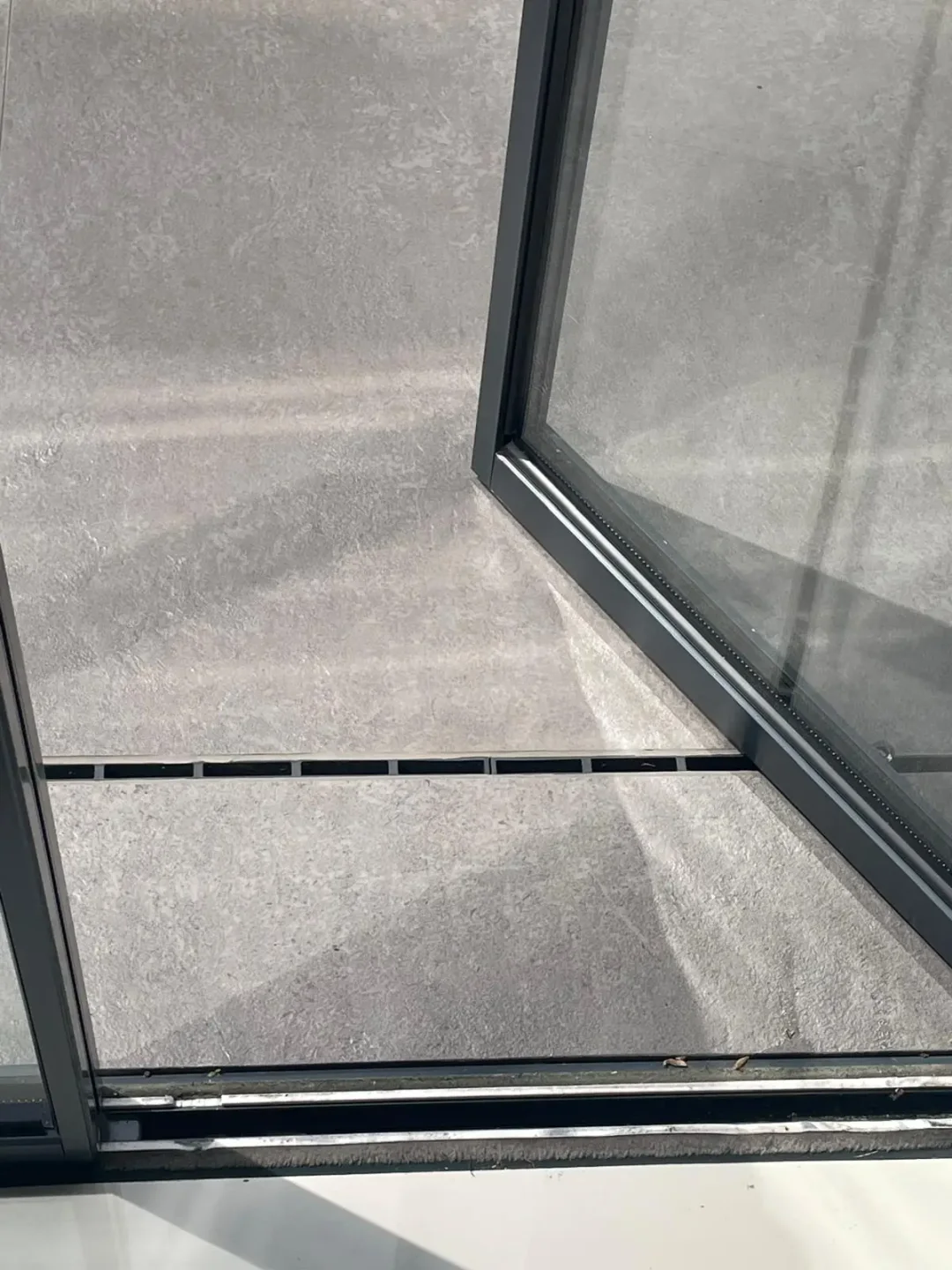

Aluminium sliding patio doors operate on precision-engineered tracks, letting large glass panels glide smoothly past one another. The slim frames create wide openings without the space requirements of hinged systems. Double and triple-track configurations offer flexibility in how you arrange the panels, while the robust nature of aluminium supports glass heights up to ceiling level.

Recent advances in roller technology mean these doors now move with minimal effort. High-grade stainless steel wheels, housed within protective casings, run along aluminium tracks that resist debris build-up. This combination prevents the sticking or jumping that often affects lesser-quality systems.

Track designs vary between manufacturers, affecting both performance and maintenance needs. Top-hung systems keep the bottom track free from dirt but require stronger overhead support. Bottom-rolling designs spread the weight across the floor track, suiting most standard installations. Quality aluminium glass doors incorporate adjustable rollers, allowing fine-tuning of panel alignment over time.

Bifolding Systems

Modern aluminium framed doors that fold back on themselves have changed how we use our living spaces. The panels fold and stack neatly against walls, creating broad openings without permanent space requirements. Traffic doors, built into the system, provide everyday access without operating the entire set.

Aluminium’s strength permits very slimline bifold doors while supporting the weight of multiple glass panels. Each panel connects to its neighbour via robust hinges, with top and bottom pins ensuring smooth operation. The running gear – a combination of carriages, guides, and hinges – determines how well the system works long-term.

French Doors

Traditional styling meets modern materials in aluminium french doors. These hinged double doors open outwards or inwards, depending on space requirements. Multipoint locking systems, integrated into the frame, provide security without compromising the clean lines that aluminium makes possible.

The frame design differs from sliding or folding systems, incorporating deeper profiles that house sophisticated locking mechanisms. Despite these differences, aluminium glass doors in the French style maintain the slim sightlines that make the material popular. Manufacturers often add a central mullion for extra stability, though mullion-free designs exist for completely clear openings.

Slide and Turn Doors

This innovative system combines elements from sliding and pivoting doors. Individual panels slide along a single track, then pivot at the ends to stack perpendicular to the frame. Unlike bifolds, each panel moves independently, allowing for partial opening configurations that bifold doors can’t match.

The engineering behind slide and turn systems showcases aluminium’s adaptability. Each panel needs precise alignment and robust hardware to slide and pivot smoothly. The frames include specialised guides and pivots, yet maintain the slim profiles that aluminium frame doors are known for.

The weight-bearing components in these systems face unique challenges. Top-hung designs need substantial header support, while bottom-rolling versions require perfectly level tracks. Quality systems use sealed bearings and anodised running surfaces to reduce friction and prevent wear.

Advantages and Disadvantages of Aluminium Frame Doors

Common myths about aluminium frame doors persist despite advances in manufacturing and design. Modern aluminium systems differ vastly from their predecessors, particularly in thermal performance and maintenance requirements.

Cost Comparison

While aluminium framed doors often cost more initially than alternatives made from uPVC, their longevity tells a different story. The material’s durability means less spending on repairs or replacements over time.

When paired with modern glazing units, aluminium glass doors maintain their performance for decades, unlike uPVC which can yellow and weaken under UV exposure.

The price gap between materials has narrowed as aluminium manufacturing techniques improve. Advances in extrusion processes now allow for more complex profiles at lower costs. External doors made from aluminium resist damage better than timber or plastic, reducing long-term maintenance expenses.

Value Factors

Installation costs vary less between materials than many expect. Aluminium windows and doors often prove easier to fit due to their dimensional stability and lighter weight. The material’s strength allows for larger panels without additional supporting structure, potentially reducing overall project costs.

Maintenance Facts

Despite popular belief, aluminium frame doors need minimal upkeep. A simple wash with soapy water removes dirt and prevents build-up in tracks. Unlike timber, the material won’t rot, split, or need regular treatment. Powder-coated finishes resist scratches and maintain their appearance without periodic repainting.

Hardware components on patio doors made from aluminium tend to last longer than those fitted to other materials. The frames’ stability prevents misalignment that often causes sticking or binding in other door types. Running gear, hinges, and locks continue working smoothly with basic cleaning and occasional lubrication.

Energy Efficiency Reality

Modern aluminium glass doors incorporate thermal break technology that rivals or surpasses other materials. These barriers, made from polyamide strips, stop heat transfer between inner and outer frame sections. Combined with high-performance glass units, aluminium framed doors achieve impressive thermal efficiency ratings.

The myth of cold aluminium stems from older designs without proper thermal separation. Today’s systems use multiple chamber profiles and sophisticated gasket designs to prevent heat loss. Independent testing shows modern aluminium frame doors match or exceed the insulation values of comparable uPVC products.

Temperature control works both ways – these doors help keep homes cool in summer and warm in winter. The material’s stability means weather seals maintain consistent contact, preventing drafts that commonly develop with other materials as they age and move. This stability also helps maintain the door’s thermal performance over its lifetime.

Hardware Compatibility

Quality locks and handles work particularly well with aluminium’s strength. The material provides solid anchorage points for multipoint locking systems, improving security without compromising the frame’s integrity. Modern aluminium doors accept the same high-security hardware as other materials while maintaining slimmer profiles.

The metal’s dimensional stability means handles and locks stay properly aligned year after year. This reduces the adjustments often needed with other materials that expand, contract, or warp with weather changes. Manufacturers can machine aluminium frames precisely, creating better seals around locking points.

Colours and Finishes for Aluminium Frame Doors

Modern aluminium frame doors offer extensive colour options beyond the traditional silver finish. Powder coating technology allows for precise colour matching while providing a tough, long-lasting surface that resists scratches and fading.

Standard vs Custom Colours

The most popular shades for aluminium framed doors include anthracite grey, black, and white, matching current architectural trends. RAL colour systems let manufacturers produce exact colour matches, useful when coordinating aluminium windows and doors across a property. Dual colour options allow different finishes inside and out, giving flexibility in design schemes.

Metallic finishes create distinct visual effects as light conditions change throughout the day. These specialised coatings contain tiny metal particles that reflect light differently depending on viewing angle. Unlike painted timber or foiled uPVC, the finish becomes part of the material rather than sitting on top.

Surface Properties

Quality powder coating involves multiple stages of preparation and application. Manufacturers first clean and etch the aluminium surface, creating microscopic texture that helps the coating bond. This process, combined with controlled curing, produces finishes that resist chipping and peeling even in harsh conditions.

Finish Types Explained

Aluminium glass doors can feature various surface textures beyond smooth gloss or matte. Textured finishes hide minor scratches and fingerprints while providing extra grip on handles and frames. These finishes work particularly well on minimal sliding doors where large surfaces might otherwise show marks easily.

Anodising offers an alternative to powder coating, creating a hard oxide layer that becomes part of the metal itself. This microscopically porous surface takes on subtle colour variations during the process. While available in fewer colours than powder coating, anodised finishes provide excellent durability and a distinctive metallic appearance.

Matching Hardware

Handle designs and other visible hardware need careful selection to complement frame colours. Modern aluminium frame doors often feature colour-matched handles and hinges, creating a cohesive look. Manufacturers develop specific coating processes for moving parts that resist wear while maintaining colour consistency.

Glass room dividers benefit from carefully chosen frame colours that work with both adjoining spaces. The wide range of colours available means these internal aluminium glass doors can either stand out as feature elements or blend subtly with surrounding décor. Neutral tones often work best for these applications, letting the glass remain the focal point.

Special Effects

Recent innovations in coating technology have introduced unique finishes like concrete effects and wood grain textures. These specialised treatments give aluminium framed doors distinctive appearances while maintaining the material’s inherent benefits. Though more costly than standard finishes, they offer creative possibilities for specific architectural requirements.

Some manufacturers now offer custom patination processes that speed up natural weathering effects. These controlled chemical treatments create unique surface patterns that would typically take years to develop naturally. The results provide character while maintaining the protective properties of standard finishes.

Technical Details

Modern aluminium frame doors incorporate numerous engineering features that affect their performance and durability. The technical specifications determine how well these doors work in different situations and environments.

Frame Depths

Frame depth affects both structural strength and thermal insulation in aluminium framed doors. Standard profiles range from around 45mm for interior sliding doors to 70mm for external systems. Deeper frames accommodate larger glass units and more sophisticated thermal breaks, while allowing for robust multi point locking system integration.

Aluminium glass doors benefit from carefully calculated frame geometry. Internal chambers provide rigidity without excess weight, while dedicated drainage channels prevent water accumulation. The frames’ construction allows for concealed fixings and clean lines, particularly important in aluminium entrance doors where aesthetics matter.

Profile Design

Today’s aluminium frame doors use advanced profile designs that improve performance without increasing visible frame width. These profiles incorporate multiple internal webs that add strength where needed while reducing material use elsewhere. Quality manufacturers optimise these designs through computer modelling and real-world testing.

Glass Options

Glass choice strongly influences how aluminium frame doors perform. Double-glazed units remain popular, though triple glazing suits locations needing extra thermal or acoustic insulation. Low-emissivity coatings and argon gas filling improve insulation without affecting transparency.

The strength of aluminium frame doors permits larger glass panels than other materials allow. Standard sizes typically max out at 2.4 metres high, though specialist systems can accommodate taller panels.

Hardware Choices

Secure patio doors need robust locking mechanisms that work with the frame design. Quality systems use stainless steel components to prevent corrosion, with multiple locking points spaced along the frame. The metal’s strength allows for secure fixing of heavy-duty hinges and handles without frame reinforcement.

Modern hardware options for aluminium framed doors include automated opening systems and smart locks. These components require precise mounting points and cable channels, which manufacturers integrate into the frame profiles. Electronic systems benefit from aluminium’s stability, as the mounting points maintain perfect alignment over time.

Security Features

Security in aluminium frame doors starts with the frame itself. Interlocking sections and anti-lift devices prevent forced entry, while toughened or laminated glass adds another security layer. Lock keeps bolt directly into the frame rather than plastic inserts, creating stronger locking points.

The profile design includes specific security features like anti-snap cylinder guards and reinforced corners. Manufacturers machine these details directly into the aluminium profiles, creating integrated security that doesn’t rely on add-on components. Modern systems meet current security standards without compromising the slim sightlines that make aluminium popular.

Installation Requirements

Installing aluminium frame doors properly ensures optimal performance and longevity. The process involves precise measurements, proper structural support, and attention to building regulations.

Structural Support

Building regulations specify load-bearing requirements for aluminium framed doors based on size and configuration. Floor to ceiling sliding doors need particularly robust head supports to carry the weight. Steel beams or reinforced concrete lintels distribute the load evenly across the opening, preventing sagging or misalignment.

The base support for aluminium glass doors demands careful preparation. Installers must create a level threshold that can support the entire system while allowing for drainage. Some configurations need steel reinforcement beneath the threshold, especially with wider openings or multiple panels.

Space Needed

French doors need clearance for their swing arc, while aluminium frame doors that slide or fold require specific stack space. Track-mounted systems need precise calculations for panel overlap and stacking depth. The space above the frame must accommodate head tracks and running gear without conflicting with existing structures.

Different opening styles need varying amounts of side space. Sliding systems require pocket space or overlap clearance, while folding doors need room for stacked panels. The frame depth of aluminium framed doors affects how much wall thickness you’ll need for proper fixing and insulation.

Building Regulations

Current building regulations set specific requirements for aluminium frame doors regarding thermal performance, safety glass, and emergency exits. These rules vary by location and door type, with stricter standards applying to main entrances and escape routes.

Part L compliance requires documented thermal performance through proper thermal breaks and glazing specifications. Installers must also ensure adequate ventilation, particularly in areas where doors replace former window openings. Fire safety regulations might restrict certain door types in specific locations.

Ground Preparation

The success of sliding and folding aluminium glass doors depends heavily on proper ground preparation. Drainage channels need careful integration with existing ground levels to prevent water ingress. Threshold options vary from fully recessed to weather-rated surface-mounted types, each needing specific ground conditions.

Some installations require additional groundwork to achieve level thresholds. This might involve adjusting floor heights or creating new drainage paths. The threshold design must balance accessibility requirements with weather protection, particularly for external doors.

Access

Door position affects both practical use and compliance with building regulations. Opening directions and handle positions need careful planning, especially for aluminium frame doors in public spaces. Access regulations specify minimum clear openings and maximum threshold heights.

For automated systems, installers must plan cable routes and power supply locations during the early stages. These elements need integration into the building structure while remaining accessible for maintenance. Control panel positions need careful thought to balance convenience with aesthetics.

Aluminium Frame Doors Buying Tips

The process of choosing aluminium frame doors involves several key decisions that affect long-term satisfaction. Careful research and asking the right questions helps avoid common pitfalls and ensures you get what you need.

Quality Markers

High-quality aluminium framed doors show their value in the details. Precise corner joints indicate careful manufacturing, while smooth operation suggests quality hardware. Well-made frames have consistent gaps between panels and even sight lines across all elements.

The quality of powder coating provides another reliable indicator. Good finishes feel smooth without orange-peel texture or rough spots. Aluminium glass doors should show no signs of coating gaps near joints or hardware mounting points. Check that colours match exactly between frames, panels and trim pieces.

Manufacturing Signs

Look for these quality indicators when examining samples:

- Clean, tight corner joints

- Smooth-rolling wheels or hinges

- Even gasket compression

- Precise panel alignment

- Consistent powder coating

- Well-fitted hardware

- Clear drainage holes

- Complete weather sealing

Warranty Coverage

Quality aluminium frame doors come with comprehensive warranties that protect your investment. The best manufacturers offer different coverage periods for various components. Frame warranties typically span 20-25 years, while hardware coverage ranges from 5-10 years.

Powder coating warranties deserve special attention. Good manufacturers guarantee their finishes against peeling, blistering and excessive fade for at least 10 years. These guarantees often include specific provisions about coastal locations or other challenging environments.

Questions for Suppliers

Reputable suppliers of aluminium framed doors welcome detailed questions about their products. Ask about the source of their frames and hardware – quality manufacturers will happily share this information. Request specific details about thermal break construction and glass specifications.

Installation expertise matters as much as product quality. Good suppliers maintain trained installation teams or can recommend qualified installers. They should explain their quality control process and after-sales service clearly, including how they handle any issues that might arise.

Price Comparisons

When comparing quotes for aluminium glass doors, look beyond the bottom line. Lower prices might reflect reduced specification in hidden areas like thermal breaks or hardware quality. Compare the details of what each quote includes, particularly regarding installation and aftercare service.

About SunSeeker Doors

With over 20 years of experience, SunSeeker Doors remains at the forefront of door design with our quality-tested patio doors and related products, including the bespoke UltraSlim aluminium slide and pivot door system, Frameless Glass Doors, and Slimline Sliding Glass Doors. All of our doors are suitable for both internal and external use.

To request a free quotation, please use our online form. You may also contact 01582 492730, or email info@sunseekerdoors.co.uk if you have any questions.