Made to Measure Sliding Doors: Planning Your Project

Table of Contents

Why Choose Made To Measure Sliding Doors?

Most homeowners find themselves limited by standard-sized doors that don’t quite meet their needs. Made to measure sliding doors solve common issues like gaps, draughts, and operational problems that arise from installing pre-made doors in non-standard openings.

Perfect Fit Guarantee

Precision in manufacturing starts with detailed measurements of your door opening’s width, height, and depth. Professional surveyors account for structural quirks like uneven walls or floors that could affect the door’s operation. These measurements ensure made to measure sliding doors fit perfectly within the available space, preventing issues that often plague standard-sized installations.

Modern sliding door systems rely on exact specifications to perform properly. Even small discrepancies in door measurements can lead to problems with smooth operation over time. The manufacturing process incorporates tolerances of less than a millimetre, particularly for the track system where the door panels glide.

Quality and Durability

Made to measure sliding doors undergo rigorous quality control throughout production. Each component, from the frame sections to the glass panels, is cut and assembled specifically for your opening. The result is a door that maintains stability and smooth operation far longer than adapted standard sizes.

The manufacturing process allows for stronger corner joints and better-sealed glazing units, as there’s no need to modify pre-made components. This attention to detail at the production stage helps prevent common issues like water ingress and heat loss that often occur with standard-sized doors fitted to non-standard openings.

Long-term Performance

Materials used in made to measure sliding patio doors are selected based on the specific requirements of your installation. This might mean thicker aluminium profiles for larger panels or specialised glass coatings for south-facing installations. The result is a door that continues to operate smoothly years after installation, making it the perfect solution for homes where reliability matters.

Installation Precision

Professional installation teams work with exact specifications rather than having to adapt standard sizes on site. This precision fitting process helps prevent many common problems that arise from forcing standard-sized doors to fit non-standard openings. The installers can focus on ensuring optimal operation rather than making adjustments to compensate for size discrepancies.

Each made to measure sliding door is test-fitted at the factory before delivery, checking the operation of all moving parts. This methodical approach helps eliminate potential issues before they arise, resulting in doors that work properly from day one.

Glass Options for Custom Sliding Doors

Made to measure sliding doors demand careful glass selection to match your space’s requirements. Glass specifications directly influence thermal efficiency, privacy levels, and how much natural light enters your home.

Thermal Performance

Double-glazed made to measure sliding doors typically achieve U-values between 1.4 and 1.6 W/m²K. Triple glazing brings these values down even further, though this affects the weight and operation of each panel. Solar control coatings on the glass help regulate indoor temperatures by reflecting heat during summer while retaining warmth in winter.

Low-iron glass improves clarity and light transmission compared to standard glass, making it ideal for made to size sliding doors where views are paramount. The reduced iron content removes the slight green tinge visible in standard glass, especially noticeable in thicker panes.

Pattern Options

Decorative interlayers between glass panes offer privacy without blocking light. These range from subtle textures to bold patterns, allowing made to measure sliding doors to become striking design features while maintaining their practical purpose.

Advanced Glazing Features

Made to measure sliding doors can incorporate acoustic glass that reduces noise transmission by up to 40 decibels. This specialised glass uses laminated panes of different thicknesses to disrupt sound waves, particularly useful in urban settings or near busy roads.

Safety Standards

Toughened safety glass, required by building regulations for sliding doors, breaks into small rounded pieces rather than sharp shards. Laminated glass offers additional security by holding together when broken, thanks to an interlayer that bonds the glass panes.

The thickness of safety glass varies based on panel size and location. Larger panels in made to measure sliding doors need thicker glass to resist wind loads and maintain stability during operation. Ground floor installations often incorporate additional security features like anti-lever devices and multi-point locking systems.

Cost Factors of Made To Measure Sliding Doors

The price of made to measure sliding doors varies widely depending on materials, size, and specifications. While standard sizes might cost less initially, bespoke doors often provide better value through improved performance and durability.

Size Impact on Price

Large sliding doors typically command higher prices due to increased material costs and manufacturing complexity. A basic two-panel system measuring 2 metres wide might start at £3,000, while made to measure sliding doors spanning wider openings can reach £12,000 or more.

Glass thickness scales with panel size, affecting overall costs. Larger panels need thicker glass to maintain structural integrity and meet safety standards. This relationship between size and materials means that doubling the width of made to measure sliding doors often more than doubles the price.

Material and Hardware Costs

Aluminium frames remain popular for made to measure patio doors, balancing cost with longevity. Steel frames, while pricier, offer slimmer sightlines and increased strength. Timber frames suit traditional properties but require regular maintenance to prevent warping.

Premium hardware adds to the base cost but improves daily operation. Stainless steel rollers and multi-point locking systems increase security and smooth operation. These components often carry longer warranties, justifying their higher initial cost through extended service life.

Glass Specifications

Specialised glass treatments increase costs substantially. Triple glazing adds approximately 30% to the price compared to double glazing, while smart glass can double the overall cost of made to measure sliding doors. Solar control coatings typically add 15% to glass costs but reduce energy bills long-term.

Installation Expenses

Professional installation usually accounts for 15-20% of the total project cost. Complex installations involving structural work or unusual access requirements might increase this percentage. Most manufacturers insist on professional fitting to validate warranties.

Ongoing Costs

Annual maintenance costs remain relatively low for made to measure sliding doors when compared to standard units. The precise fit reduces wear on components, while high-quality materials resist deterioration better than budget alternatives.

Energy efficiency affects long-term running costs. Well-fitted made to measure sliding doors with modern glass specifications can reduce heat loss by up to 40% compared to older installations, leading to lower heating bills. The exact savings depend on your home’s heating system and local climate.

Warranty Coverage

Comprehensive warranties often come standard with made to measure sliding doors, protecting your investment. Frame warranties typically extend to 20 years, while hardware and sealed units carry shorter terms. Some manufacturers offer extended coverage for an additional fee, particularly useful for complex mechanisms or special glass types.

Design Styles and Frame Materials

Made to measure sliding doors offer numerous design possibilities through different frame materials and styles. Each material brings distinct qualities that suit various architectural approaches, from ultra-modern to traditional.

Modern Minimal Frames

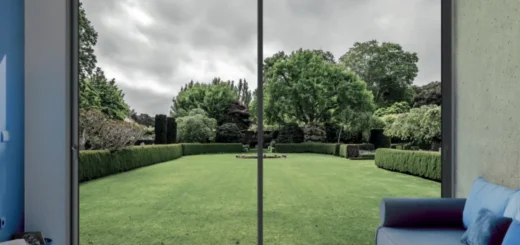

Slim-framed aluminium framed doors create clean lines and expansive glass areas. Modern made to measure sliding doors can achieve frame depths of just 20mm around the glass, pushing the boundaries of what’s structurically possible while maintaining thermal efficiency.

The structural properties of aluminium allow for taller and wider panels than other materials. These larger panels reduce the number of vertical frames needed, creating uninterrupted views. Powder-coated finishes protect the aluminium while providing precise colour matching to existing windows or architectural features.

Contemporary sliding glass doors often incorporate concealed frames within walls and ceilings. This detail creates the illusion of a wall of glass, particularly striking in corner installations where two sets of made to measure sliding doors meet at right angles.

Frame Depth Options

Frame depth influences thermal performance and panel stability. Deeper frames allow for larger sealed units and improved insulation but increase the visible frame width. The optimal depth depends on panel size, site exposure, and thermal requirements.

Traditional Style Frames

Made to measure patio doors for period properties often feature wider frames that echo traditional timber proportions. These designs incorporate decorative elements like ovolo mouldings or Georgian bars while maintaining modern thermal standards.

Composite materials combine timber’s traditional appearance with aluminium’s weather resistance. The internal timber face can be stained or painted to match interior woodwork, while external aluminium cladding protects against weathering.

Material Properties

Aluminium offers exceptional strength-to-weight ratios, allowing interior sliding doors to operate smoothly on minimal track systems. The material resists warping and requires little maintenance beyond occasional cleaning and lubricating moving parts.

Steel frames provide even greater strength than aluminium, though at a higher cost. This strength allows for incredibly slim sightlines, particularly valued in heritage renovations where original steel windows are being replaced with made to measure sliding doors.

Design Integration

Frame design must complement surrounding architecture while meeting practical requirements. Victorian properties often benefit from frames with period details, while modern homes might suit flush floor tracks and minimal visible hardware.

Careful material selection helps made to measure sliding doors harmonise with existing features. A modern extension to a period property might use bronze-anodized frames to complement original brass hardware, creating visual continuity between old and new elements.

Frame Finishes

Powder coating offers hundreds of RAL colours with different textures and gloss levels. These finishes resist fading and scratching better than wet paint, particularly important for exterior surfaces exposed to UV light and weather.

Metallic finishes add depth to frame surfaces, changing appearance throughout the day as light conditions vary. These subtle effects help large made to measure sliding doors integrate with their surroundings rather than dominating the facade.

Customising Door Configurations

Made to measure sliding doors come in various arrangements to suit different spaces and uses. Panel configuration choices impact usability, maintenance requirements, and visual proportions.

Multi-Panel Options

Room dividers created with made to measure sliding doors often use multiple panels that stack to one side. The number of panels influences the stack depth when open – each panel typically adds 50-70mm to the overall stack width.

Three-panel configurations offer flexibility for wide openings. Two panels might slide past a fixed panel, creating a two-thirds opening, while made to measure patio doors spanning very wide apertures might use four or more panels that slide in opposing directions.

Corner installations need careful planning to maintain smooth operation. When two sets of slim profile sliding doors meet at a corner without a post, the panels must be precisely aligned. This design creates spectacular open corners but requires robust floor support.

Stack Positions

Panel stacking positions depend on wall space and room layout. Fitted sliding doors can stack externally, sliding completely clear of the opening, or internally, remaining partially visible when open. Centre-opening designs split the stack between two sides, useful where wall space is limited.

Track Systems

Single and double track options suit different uses. Single tracks work well for simple two-panel made to measure sliding doors, while double tracks allow panels to pass each other, increasing opening options.

Hidden tracks installed within floor finishes create minimal visual interruption. This detail requires deeper floor build-ups but eliminates trip hazards. Exposed tracks might sit proud of the floor or recess partially, offering easier installation with similar operation.

Opening Configurations

Monorail systems fix one panel while the other slides. This arrangement provides stability and suits made to measure sliding doors where only partial opening is needed. The fixed panel carries more weight, allowing slimmer frames for sliding sections.

Multi-slide systems need precise alignment between tracks. Each panel rolls independently, distributing weight evenly across the system. This arrangement works particularly well for large installations where individual panel weights must stay manageable.

Panel Movement

Lift-and-slide mechanisms raise panels slightly during operation, reducing friction and wear. This technology permits larger, heavier panels in made to measure sliding doors while maintaining easy movement.

Traditional sliding mechanisms suit lighter panels and internal applications. These systems cost less but might require more effort to operate, particularly in wider installations where multiple panels move together.

Hardware Integration

Handles and locks need careful positioning to work with different panel arrangements. Intermediate panels might use recessed pulls to prevent interference when sliding, while primary panels carry main locking hardware.

Security measures vary by configuration. Multi-point locking systems secure primary sliding panels, while secondary panels might use simpler catches or interlocks. The specific requirements depend on insurance standards and building regulations for your installation type.

Finishes and Hardware

Made to measure sliding doors offer extensive finishing options that meet practical and visual requirements. From metallic coatings to textured surfaces, each finish type brings specific benefits and maintenance needs.

Colour Options

Powder coated aluminium sliding doors provide lasting colour stability through a three-stage coating process. The base coating bonds to the metal, while intermediate layers build depth and texture. Final clear coats protect against UV damage and scratches.

Standard RAL colours form the foundation of most made to measure sliding doors, though exact matches to paint brands can allow perfect coordination with interior schemes. Custom colour mixing services can replicate heritage shades or match corporate branding requirements.

Anodised finishes penetrate the aluminium surface rather than coating it. These metallic finishes resist scratches better than powder coating but offer fewer colour options. The anodising process creates subtle variations across surfaces, particularly noticeable in natural bronze and champagne shades.

Surface Textures

Textured finishes on made to measure internal sliding doors hide fingerprints and minor scratches better than smooth surfaces. Available textures include:

- Fine texture – subtle, even grain

- Coarse texture – more pronounced, industrial feel

- Wood grain – mimics timber surfaces

- Matt – reduces glare and reflection

- Metallic – adds depth through metal flakes

Handle Designs

Pull handles need careful sizing to suit panel weights and user requirements. Longer handles provide better leverage for moving heavy made to measure sliding doors, while shorter styles suit smaller panels or areas with limited space.

Flush handles recess completely into door frames, preventing interference between sliding panels. These designs often incorporate locks and latches within their housing, maintaining clean lines while providing necessary security features.

Hardware Finishes

Made to measure patio doors typically match hardware finishes to frame colours. PVD (Physical Vapour Deposition) coatings on handles and locks resist wear better than standard plating, particularly important for frequently used external doors.

Marine-grade stainless steel suits coastal locations where standard finishes might deteriorate quickly. These specifications include higher grades of steel and additional surface treatments to resist salt spray corrosion.

Special Effects

Dual-colour options allow different finishes inside and out. This flexibility helps made to measure sliding doors coordinate with varying colour schemes while maintaining appropriate external appearances.

Metallic flakes within powder coatings create depth and movement across surfaces. The size and density of these flakes changes the visual effect – larger flakes produce more dramatic variations, while finer particles create subtler shimmer effects.

Protection Systems

Clear protective films guard finished surfaces during construction. These temporary coverings prevent damage from mortar splashes or grinding dust, particularly important when made to measure sliding doors are installed before other finishing trades complete their work.

Touch-up kits match original finishes for repairing minor damage. These repairs work best on textured surfaces where blend lines become less noticeable. Smooth finishes often need professional repair to maintain consistent appearance.

Finish Maintenance

Different finishes need specific cleaning approaches to maintain their appearance. Non-abrasive cleaners suit most powder coated surfaces, while anodised finishes tolerate slightly more aggressive cleaning methods. Regular cleaning prevents dirt buildup that might damage protective coatings over time.

About SunSeeker Doors

With over 20 years of experience, SunSeeker Doors remains at the forefront of door design with our quality-tested patio doors and related products, including the bespoke UltraSlim aluminium slide and pivot door system, Frameless Glass Doors, and Slimline Sliding Glass Doors. All of our doors are suitable for both internal and external use.

To request a free quotation, please use our online form. You may also contact 01582 492730, or email info@sunseekerdoors.co.uk if you have any questions.